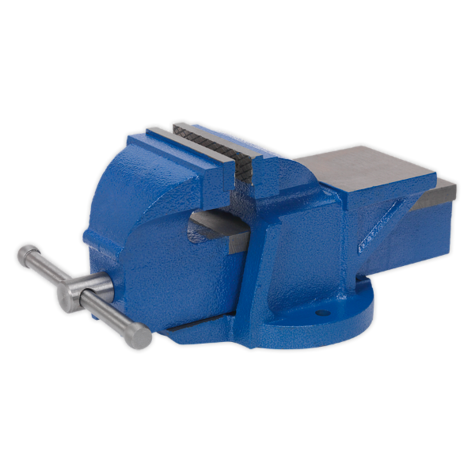

Sealey CV100XT 100mm Fixed Base Heavy-Duty Vice

£81.86

Ask a Question

Product Information

Vice 100mm Fixed Base Professional Heavy-Duty

Bench mounting, heavy-duty vice with cast iron body and replaceable, serrated steel jaws. Smooth rolled thread for accurate clamping. Model includes an anvil. Guaranteed for 2 years against breakage.

Specifications

- Make: Sealey

- Model No: CV100XT

- Jaw Size: 100mm

- Jaw Opening: 100mm

- Weight: 9.1kg

- For Warranty see: Sealey Warranties

- Standard delivery:2-3 days