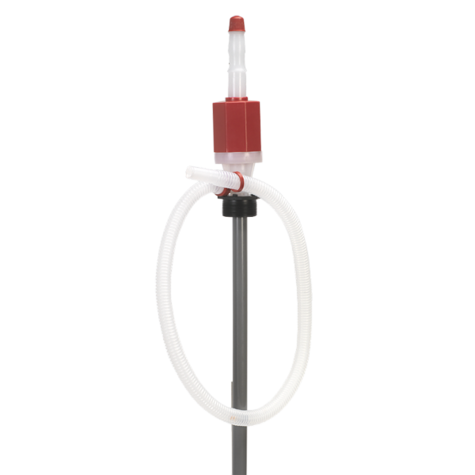

Sealey TP781 High Flow Syphon Pump

£44.12

Ask a Question

Product Information

Syphon Pump for 205ltr Drum - High Flow

- Easy-to-use polyethylene pump with self priming feature.

- Equipped with vent cap to stop discharge and flexible corrugated discharge tube.

- Suitable for oils and non-aggressive chemicals.

Specifications

- Make: Sealey

- Model No.: TP781

- EAN: 5051747522855

- Drum Suitability: 205ltr

- Delivery: 21ltr/min

- For Warranty see: Sealey Warranties

- Standard delivery: 1-2 days